Lean Manufacturing:- Lean Manufacturing Concept’ is a generic process management philosophy that is derived mostly from ‘The Toyota Production System.

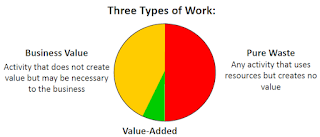

- Lean manufacturing focuses on eliminating waste in processes

- Lean manufacturing is not about eliminating people

- Lean manufacturing is about expanding capacity by reducing costs and shortening lead time between order and ship date

- Lean is about understanding what is important to the customer.

Recognize and Specify the value:-

Value is judged by the customer.

A process or activity that adds value to a product. Conventionally, VA has 3 dimensions:

The activity changes the product in shape, size & weight towards completion.

It is done right at first time (no rework).

The customer would be willing to pay for it.

Lean Manufacturing Principle:-

1- Value: Correct Specify the value of the product.

2- Vaue strim: Identify all the steps in the value stream that do not add value.

3- Flow: make the value-creating steps/process and flow smoothly.

4- Pull: Produce only the pull of customer demand.

5- Perfection: Waste elimination is an ongoing process towards completion.

- Reduced levels of inventories.

- Reduced space requirements.

- Increased product quality.

- Reduced lead times.

- Greater flexibility in product mix.

- Smoother production flow.

- Increased productivity levels.

- Worker participation in problem-solving.

- Pressure for good vendor relationships.

- Reduced need for indirect labor.

- Takt time should be decided by the Production Volume required, which reflects sales conditions exactly.to manufacture what is needed, with the speed needed, in the amount needed.

0 Comments

If you have any doubts please let me know.